High-volume manufacturing

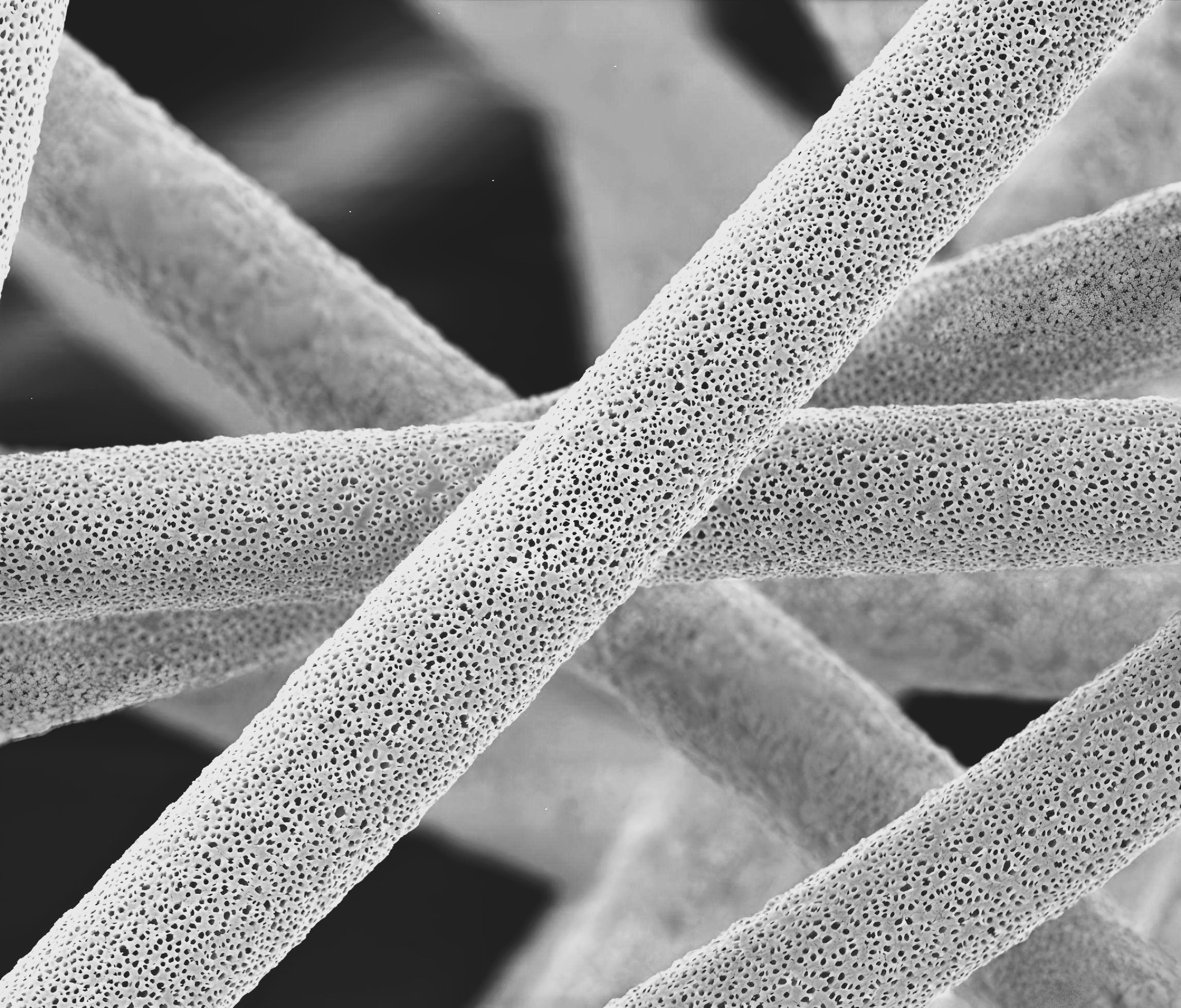

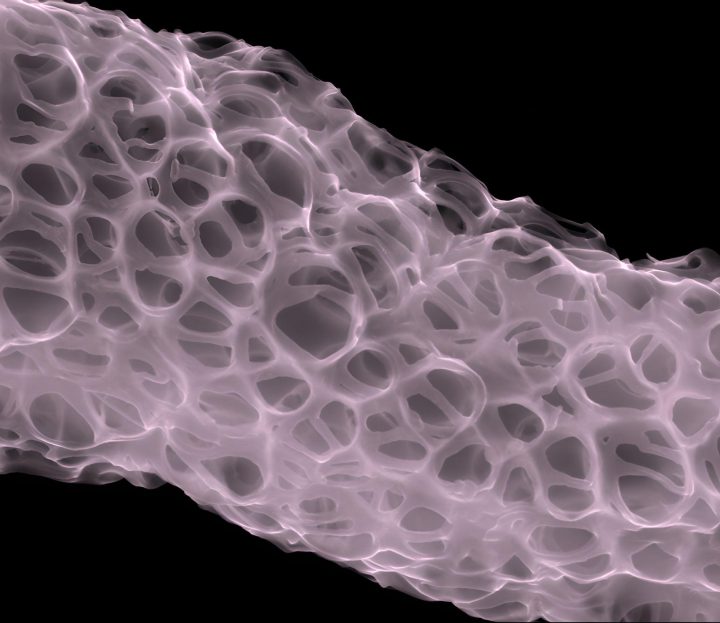

VIVOLTA’s MediSpinTM production platform offers unrivalled quality, consistency, and high-volume manufacturing of electrospun medical products.

Thanks to its fully automated, modular design, the MediSpinTM can be optimized to fulfil the design requirements of each client’s specific electrospun product.

- High-volume production system for the global commercialization of medical electrospun products

- Up to 100x higher throughput versus alternative systems

- Rigorous control of all crucial electrospinning process parameters to ensure product quality and optimize yield

- Global automation to eliminate operator influence and optimize efficiency

- Wafer-based production – not roll-to-roll – for the highest quality product with lowest scrap rate

- In-line QC sensors guarantee mesh quality and decrease manufacturing cost

- Compatible with ASTM F3510-21 standard to ensure regulatory compliance, which VIVOLTA co-authored

- IP protected by 7 patent families for differentiated innovation versus the competition

- Mesh constructs currently available; tubular constructs (valves, stents) coming soon