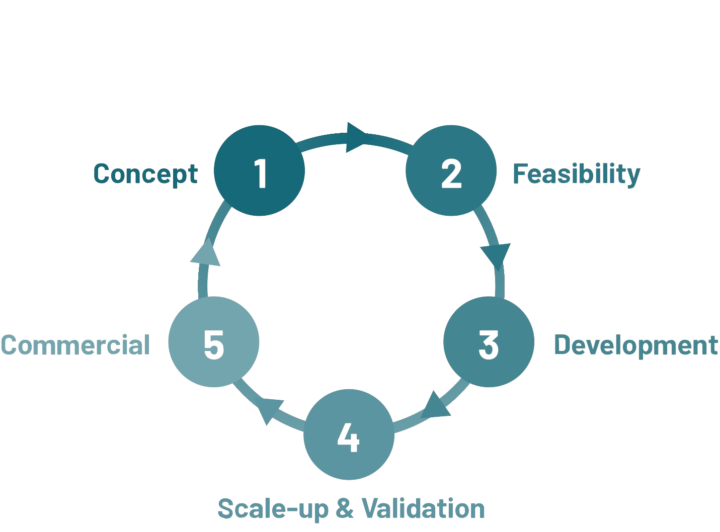

(1) Concept design: VIVOLTA works side-by-side the client to first understand the clinical need, then translating that need into design concepts made possible by medical electrospinning.

(2) Feasibility: Applying Design Thinking mechanisms, rapid, iterative prototyping based on a ‘Build-Test-Learn’ paradigm ensures most feasible concept efficiently proceeds into Development

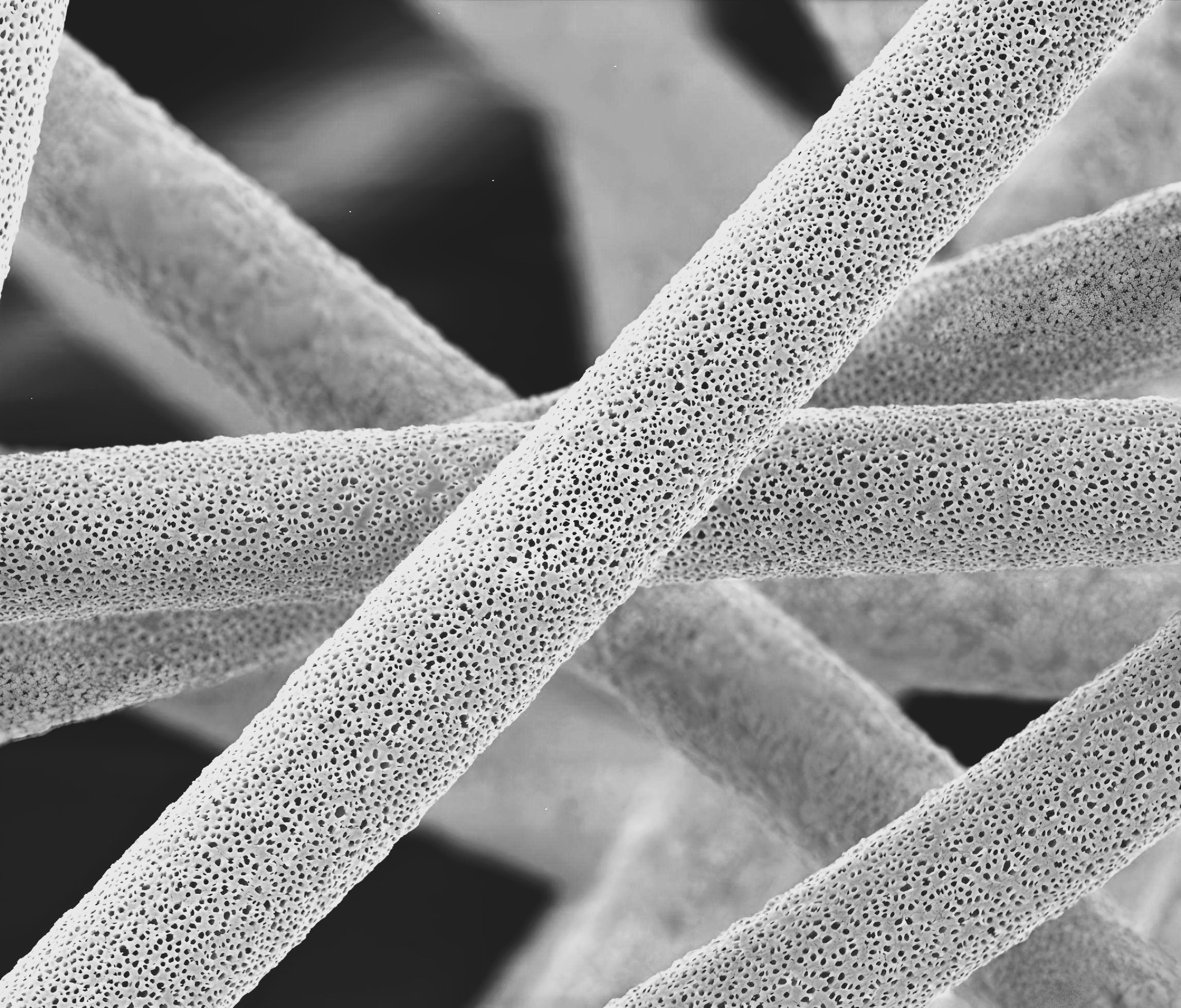

(3) Development: VIVOLTA applies a quality-by-design approach to its development activities according to Design Control principles. In this phase, VIVOLTA’s proprietary electrospinning equipment technology is leveraged and customized to meet the specific product design requirements at hand. Because of this, high quality, scalable manufacturing is designed in from the beginning of product development, not at the end

(4) Scale-up & Validation: Following product design freeze, the developed electrospinning process is transferred to a client-dedicated MediSpin production system in an ISO Class 7 cleanroom for scaled-up manufacturing. With íts fully-integrated, automated quality systems, clinical-grade products are manufactured with full traceability and 100% automated inspection.

(5) Commercial: Upon market approval, VIVOLTA is qualified according to our ISO13485 accreditation to manufacture commercial grade product in our ISO Class 7 cleanrooms. Our MediSpin production system offers in-line laser cutting and packaging for cost-effective commercialization and a simplified supply chain for our clients.